Ethernet automatic line

Classification:

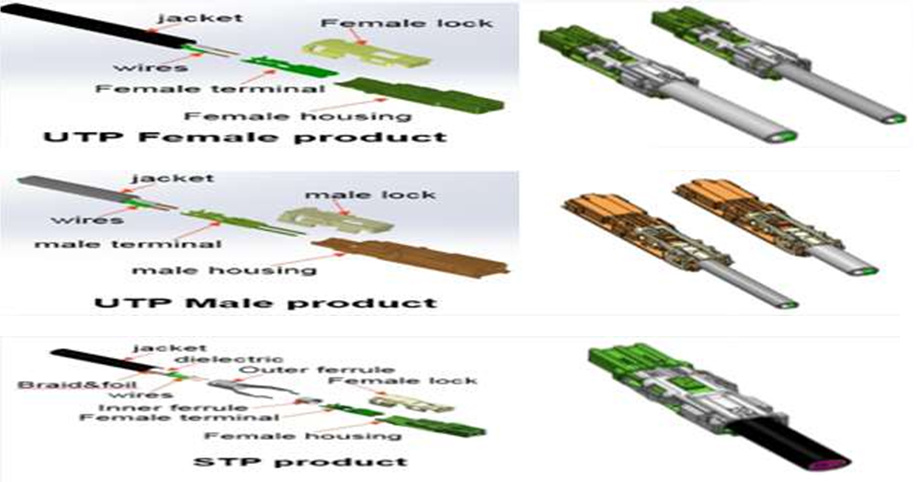

Ethernet Automatic Line

Key Words: Fixture

Function: Determining the incoming material of long wire & CCD detecting A or B end 、Half strip 、Sleeve crimping、Zero cut and strip sheath、Braid processing station、Using laser to cut the foil 、Shake to remove the foil、Separate the wires module、Cutting central rod、Folding the wires、Upper 2wires shaping + stripping+crimping、Lower 2wires shaping + stripping+crimping、shaping to HSG insertion state、Female insulator assembly station、Male insulator assembly station、Automatic feeding / assembly of female outer contact、 Automatic feeding / assembly of male outer contact、Laser marking and scanning、Ng cutting + good product receiving

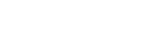

Product Description

Function: Determining the incoming material of long wire & CCD detecting A or B end 、Half strip 、Sleeve crimping、Zero cut and strip sheath、Braid processing station、Using laser to cut the foil 、Shake to remove the foil、Separate the wires module、Cutting central rod、Folding the wires、Upper 2wires shaping + stripping+crimping、Lower 2wires shaping + stripping+crimping、shaping to HSG insertion state、Female insulator assembly station、Male insulator assembly station、Automatic feeding / assembly of female outer contact、 Automatic feeding / assembly of male outer contact、Laser marking and scanning、Ng cutting + good product receiving

Highly customized: customized according to the specific needs of customers.

Multi-functional performance: it can realize automatic production of "parts assembly, welding, dispensing, labeling, locking screws, testing, packaging" and other tasks.

Improve efficiency and quality: it can improve production efficiency and ensure the stability of product quality. A piece of equipment can replace 2-10 human workers, and the cost can be recovered in about a year.

High-precision and high-speed: Using custom-developed control systems and advanced components to achieve high-precision and high-speed automated operations, it can perform tasks quickly and accurately.

Easy to integrate and operate: Upgrade and development are considered at the beginning of the design, and it can be seamlessly integrated with other automation equipment and information systems to achieve overall automation and data management.

Previous Page

None

Next Page